So in august last year I bought a 2004 registered 2003 build 5PW. It’s a category B write off after a small incident with an MPV by the previous owner (a friend of mine). It’d been partially rebuilt with new bearings all round (apart from the swing arm), fork rebuild, brake rebuild etc. What it looked like when I got it:

It had a few nice bits on it, namely a full Akra system, K&N and a PC3. It also came with a set of Harris rear sets that weren’t installed. I did also install a set of headlights!

Shortly afterwards I high sided it on a roundabout and broke my collar bone.

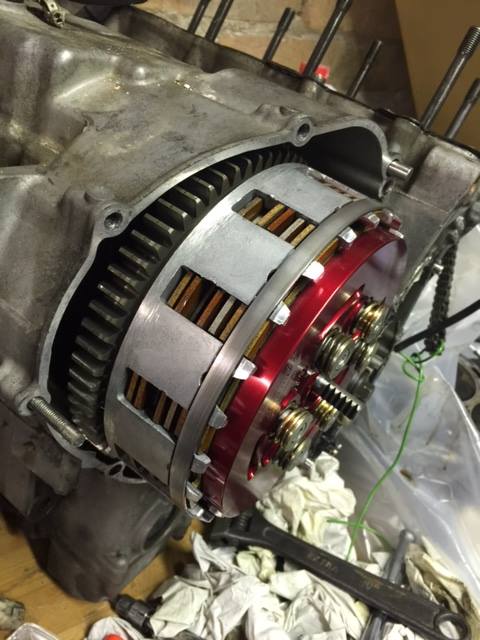

I set about getting the R1 road worthy again. It desperately needed a new clutch so I fitted one I found cheap on Demon Tweeks:

and it was terrible. Slipped almost as bad as the original one! SO I installed a Barnett top plate. It certainly sorted the clutch out! I’d been riding it around in primer for a few months but on Christmas eve I decided to plasti-dip it. I did it in the dark in 4 hours and it didn’t go brilliantly.

I also vinyl wrapped the tail:

It looked very ratty, but still rode like an R1. Here it is having a new set of Metzeler racetec’s fitted:

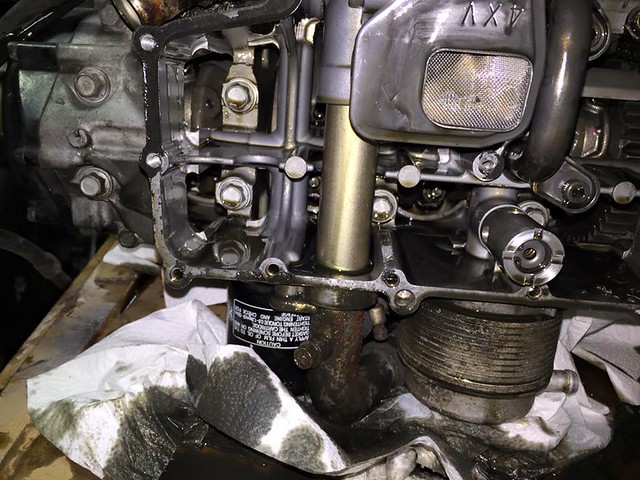

Unfortunately after a few more miles and a story I won’t go into here (No, I didn’t crash) it started making an interesting noise… the kind of noise you never want an engine to make. So I dropped the engine:

The top end was in remarkably good nick:

I was planning to rebuild the engine but once I priced up all the bearings and the work it just seemed uneconomical. Then I got hold of a rebuilt motor with the following spec:

- APE SLOTTED CAM SPROCKETS AND APE MANUAL CAM CHAIN TENSIONER

- YEC THINNER HEAD GASKET

- NEW PISTON RINGS, SHELLS, ROD BOLTS ETC

- NEW SECOND GEAR 5JJ-17221-00

- PETE BEAL PORTED HEAD.

- ALL VALVE SEATS RE-CUT TO 3-ANGLE

- ALL VALVES OIL SEALS CHANGED REPLACED WITH NEW ONES.

It was quite reasonably priced so I snapped it up. It’s literally never been fired:

Whilst dropping the engine I discovered why the bike was written off Cat B. Theres a small crack near the rear-set mount on the left of the frame. I can get this TIG welded up but whilst I’m here I figure I may as well use a new (to me at least) frame with a clean history. So I obtained a new frame. It’s got a clean V5, never written off etc. It’s been crashed, but theres only a scratch to show for it. No big deal. In the mean time, I stripped down the original engine and discovered the source of the noise. I dropped the sump off and was greeted by the following lovely sight:

The clutch has completely shattered. Brilliant.

It’s gone everywhere so I’m going to need to split the casings. Good thing is it doesn’t appear at first glance to have done much damage so the engine may be salvageable with a complete strip down, a good clean out and a new set of gaskets. Still, I’ve got my new engine to go in:

I set about stripping her down:

It would appear that the reason my original frame was written off is due to these cracks:

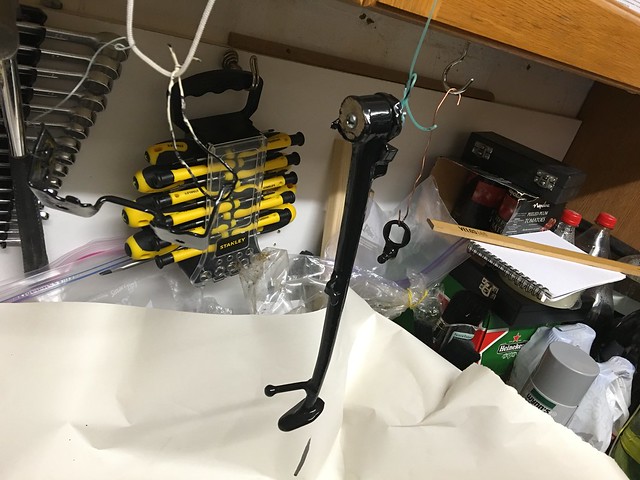

Also painted the side stand:

Today I finished stripping down the old frame and swing arm. Forks out (dropped the triple out, then took the forks out of the triple):

Then I got the shock out:

Then I needed to remove the swing arm pivot. Well, I’ve never come across a nut this seized! I had a go with a rattle gun for a good 20 mins with no luck. Heated it up with a blow torch and tried again, no luck. Tried a steel bar on a wrench, no luck. Finally, I got my friend to come over with his 5ft breakers bar, we heated the nut up and then the two of us managed to get it undone. It was obviously torqued well over the specified 120~Nm!

Now the swing arm is out, I had to remove the bearings (the frame, swing arm and subframe are getting powder coated next week and so the bearings need to be removed as if you powder coat with the bearings in the grease will run when the part is baked and ruin the powder coat). I used a Halfords trolley jack handle as a drift, heated up the swing arm and hammered them out:

I then set about removing the other swing arm fittings. All came out swimmingly apart from one very corroded bobbin bolt. I’ve got to have a couple of new threaded collar’s welded in where they’ve fallen out anyway so I’ll just get the engineering firm to deal with the stud when they TIG in the new collars (And re-tig the existing ones). Thats about where I am now. I’ve completely stripped the Frame and swing arm, I’ve just got to get the tray out of the sub frame and get the swing arm sorted then It’ll all be ready to go to the powder coaters.